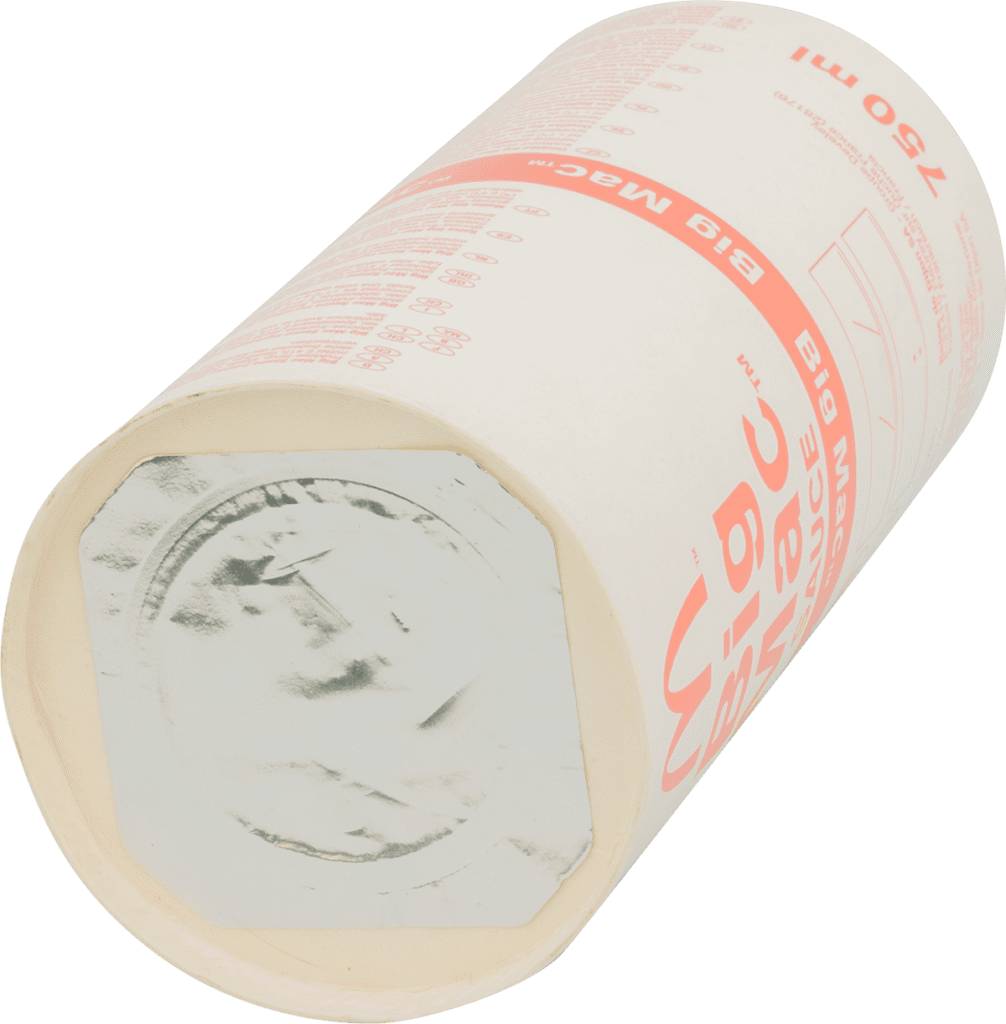

Environmentally friendly composite can machinery

In line with our mission, we manufacture equipment that uses minimal amounts of non-degradable substances. As a result, our composite can machinery consists almost entirely of one material: cardboard.

Moreover, our machines are optimised to be as energy-efficient as possible. Consequently, our composite can machinery is among the most sustainable around, both in its use and the output it yields.