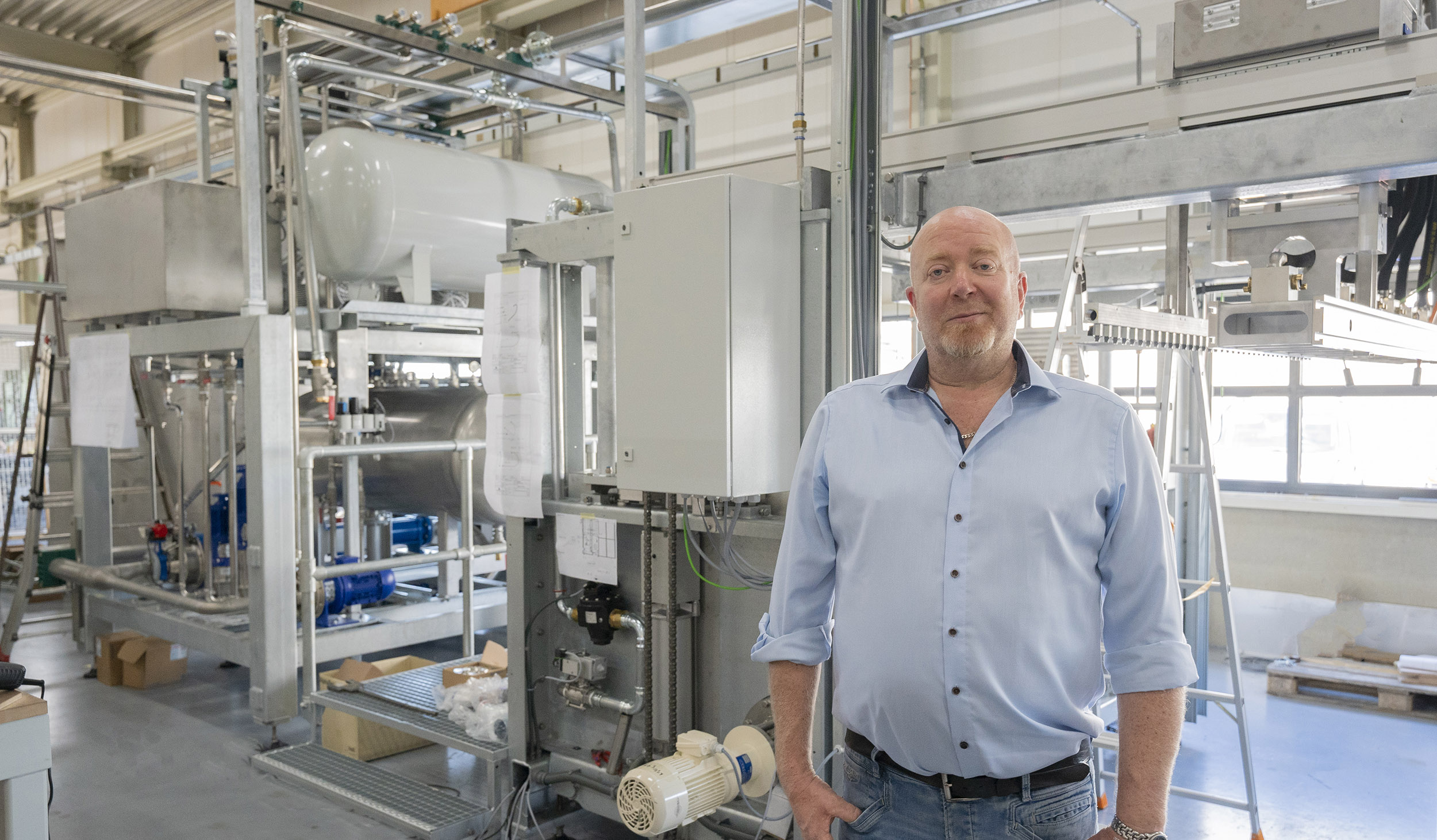

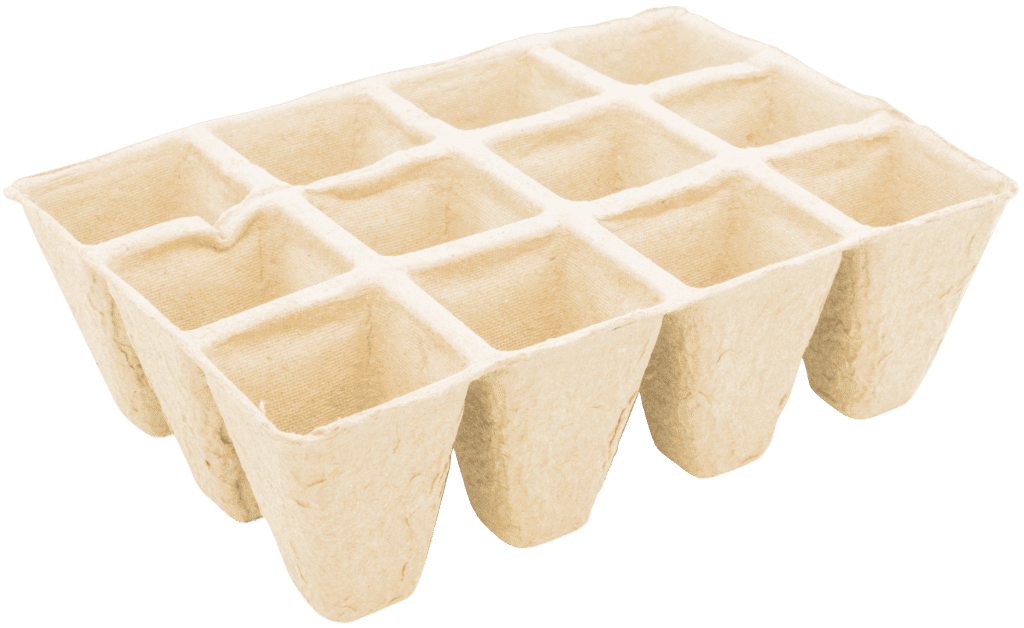

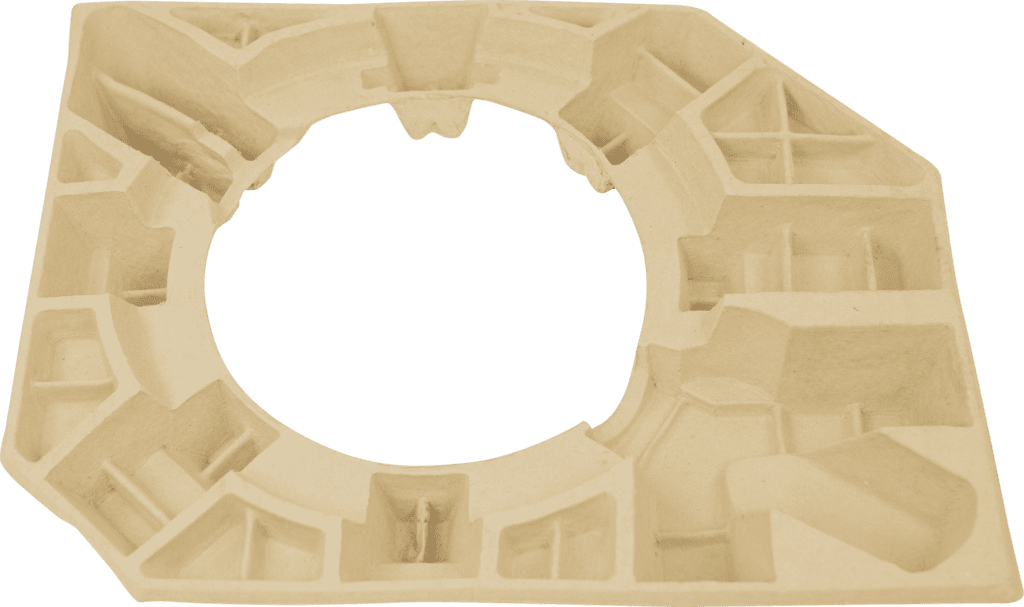

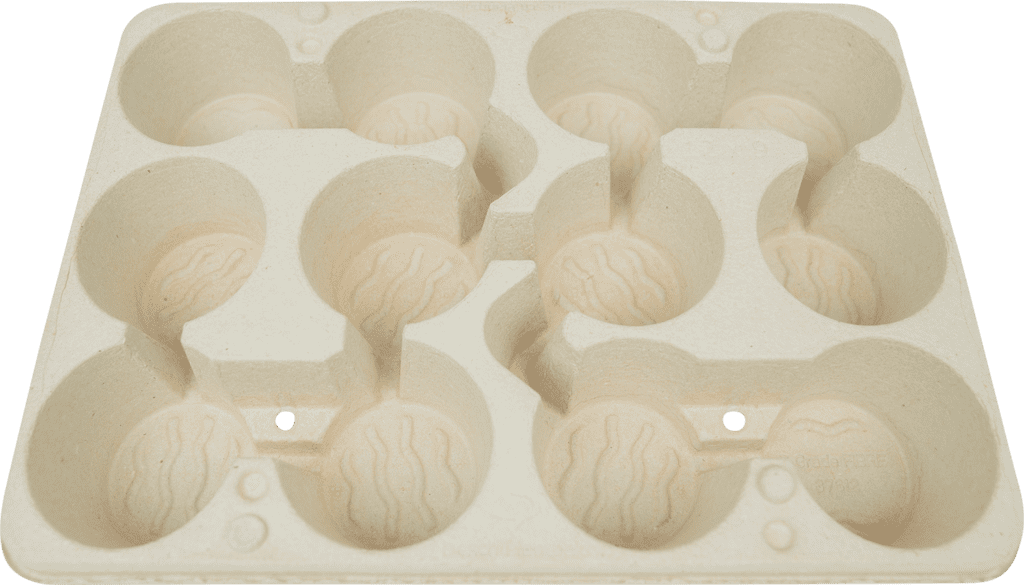

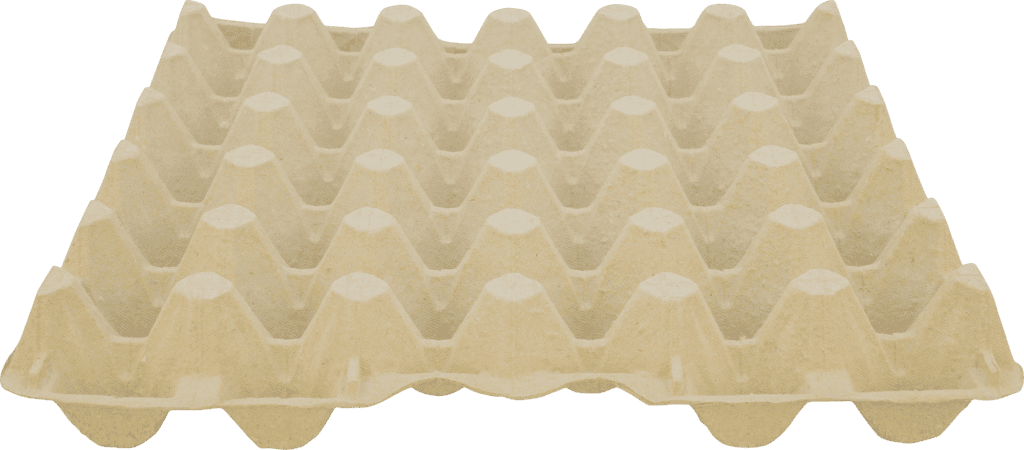

Biodegradable and economical

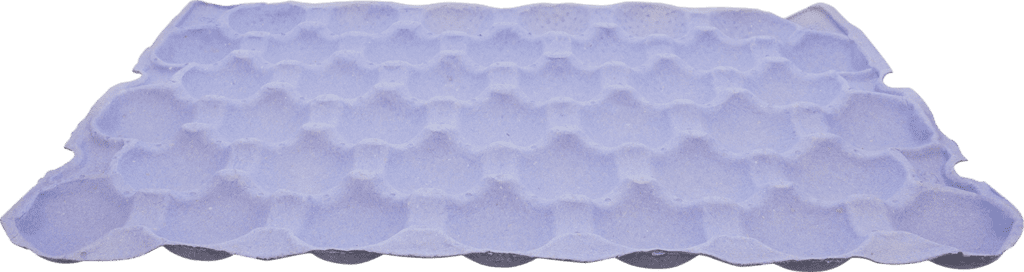

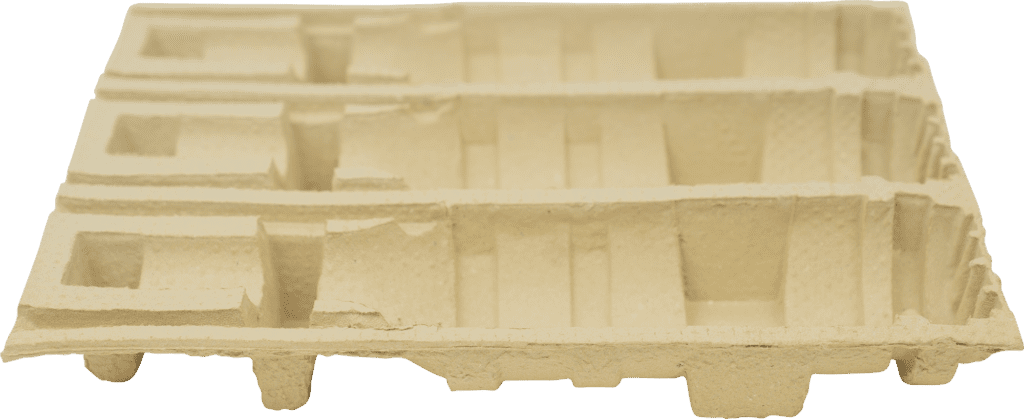

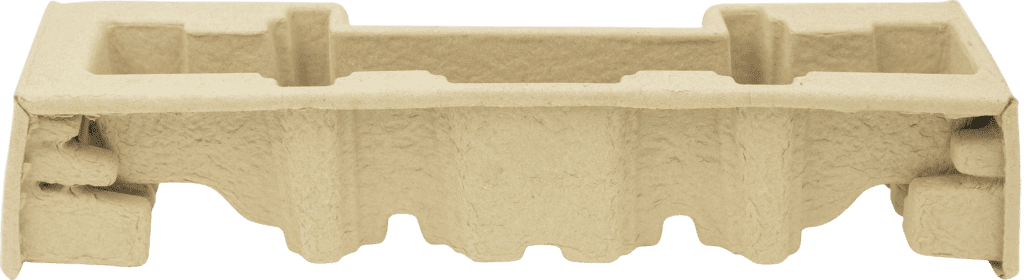

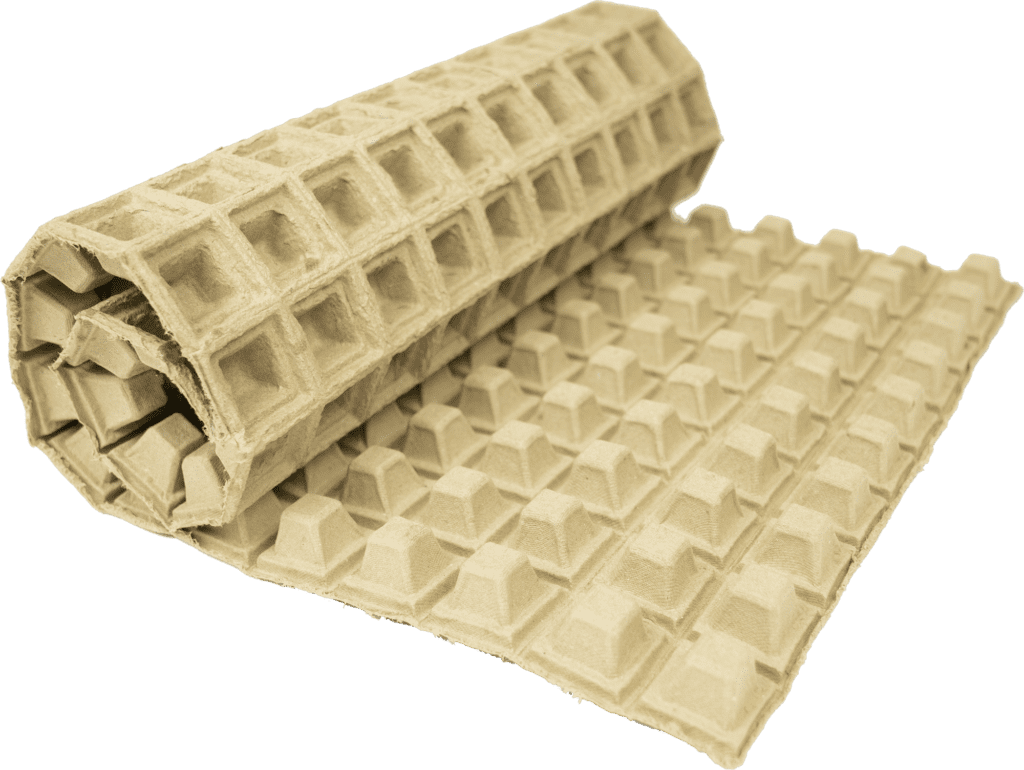

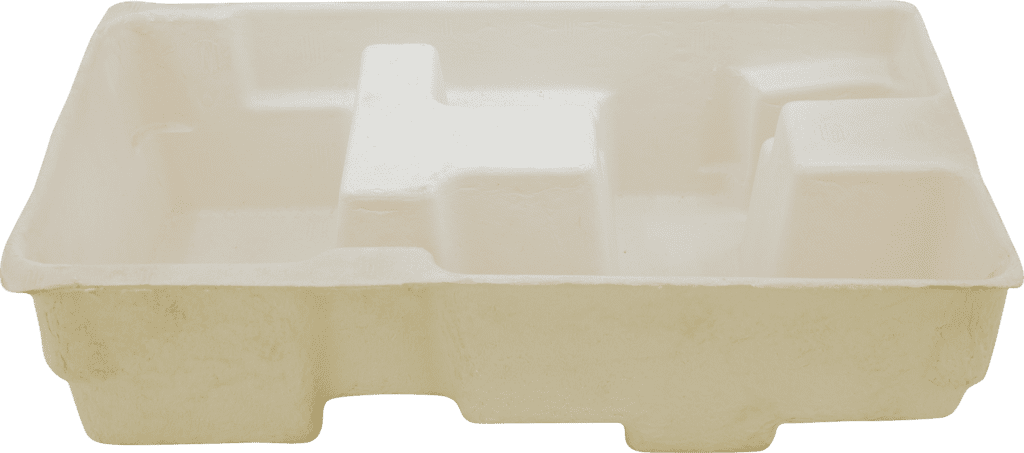

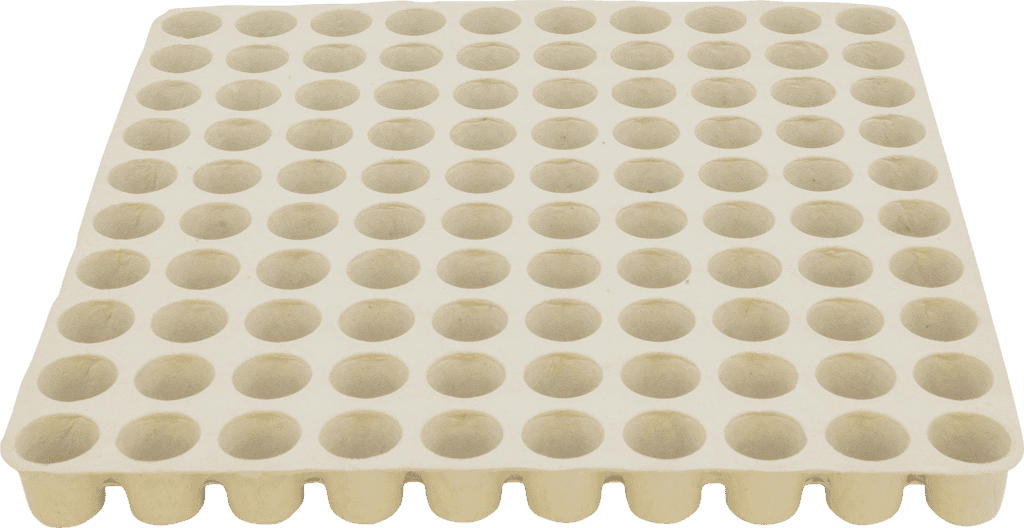

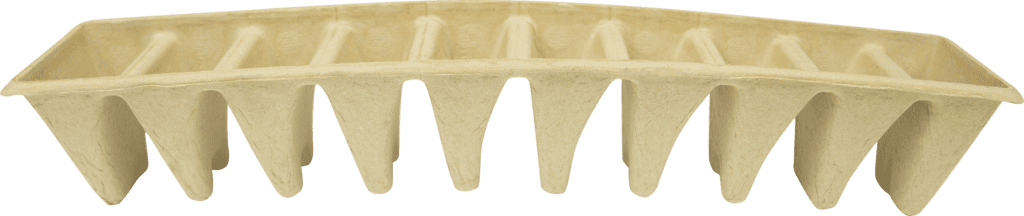

All packaging materials are robust and provide reliable protection. Made of (recycled) paper, bagasse straw and various virgin fibres, they are fully degradable. As a result, they offer a perfect alternative to plastic packaging products.

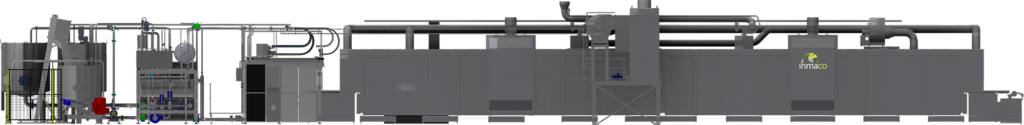

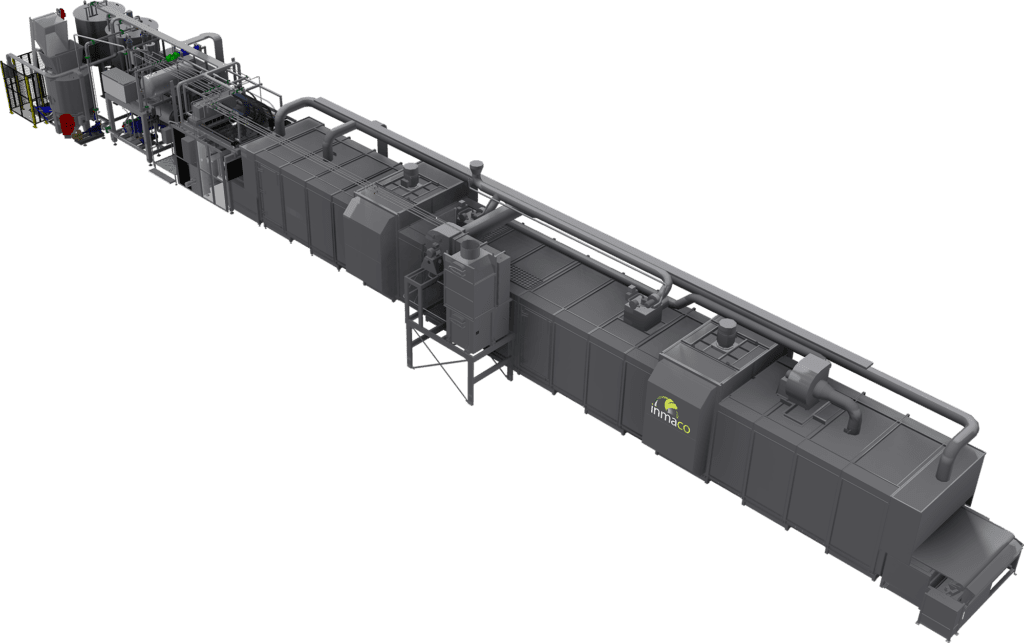

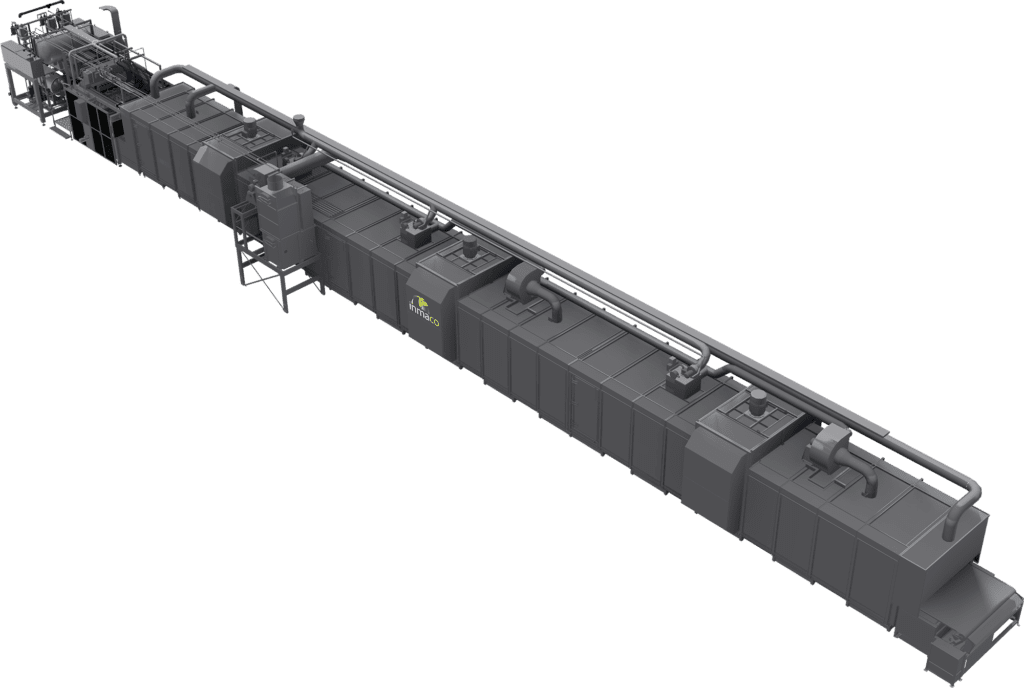

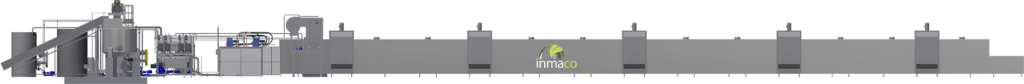

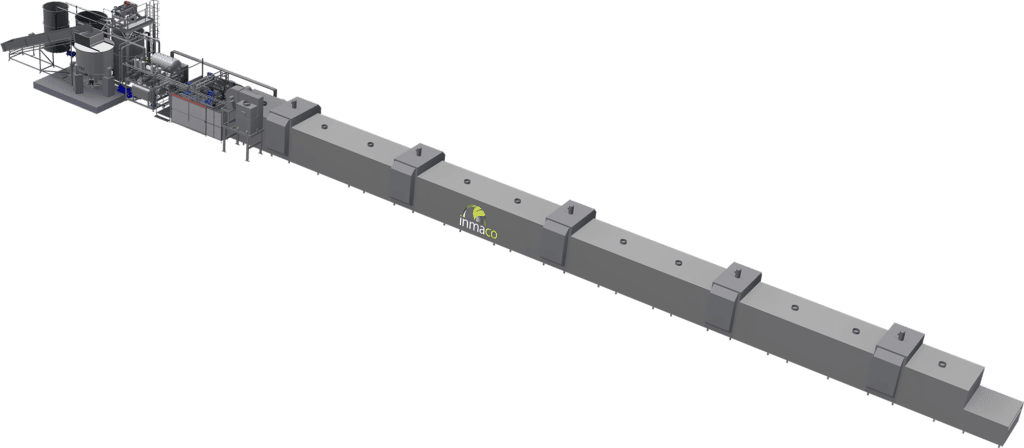

On top of their sustainable nature, our pulp moulding machines are economically priced. This is made possible by clever purchase arrangements and yearlong optimisations regarding costs and energy use.