Optimal handling

Moreover, the products are stacked, minimising the number of staff required for the production. Optionally, we can add vision systems to guarantee the quality of the products.

Moreover, the products are stacked, minimising the number of staff required for the production. Optionally, we can add vision systems to guarantee the quality of the products.

Our pulp thermoforming machines manufacture products that closely resemble thermoformed plastic materials. As such, they are sustainable substitutes with the same printing, embossing and handling opportunities as their plastic counterparts.

All our pulp thermoforming machines are custom-made for you. Should you require equipment that cannot be made with our standard designs, please note that we also manufacture machinery from scratch.

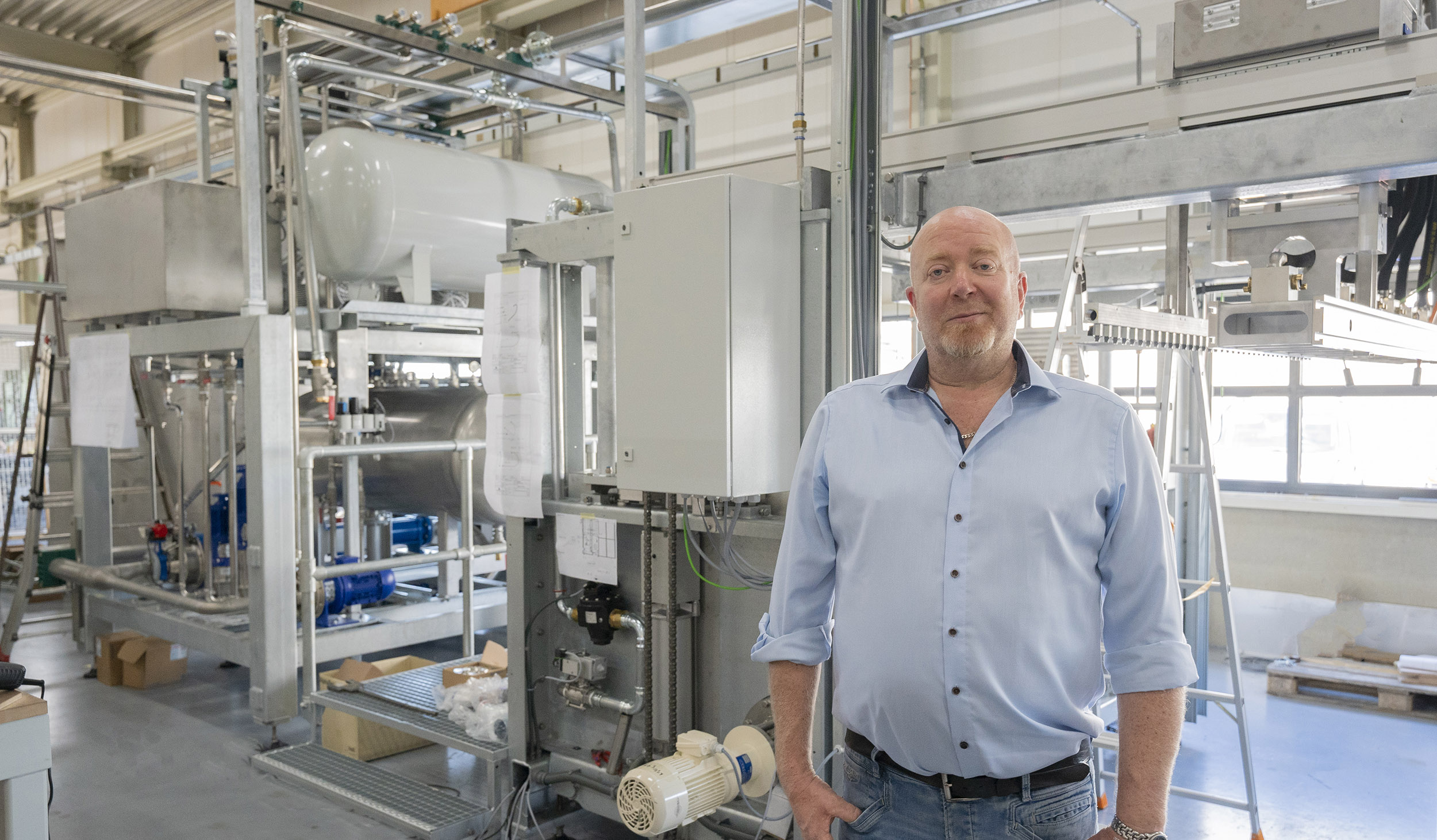

This pulp thermoforming machine is our top model. It allows the production of high volumes by automated stock preparation and increased drying capacity.

| MACHINE TYPE | MT/FP-80-3 |

| Output kg/h up to | 60-80-100 (Consistency, 35%) |

| Table size mm x mm | 1180 x 900 |

| Semi-rotating | |

| No. of drying stations | 3 |

| Pressing force | Servo hydraulic 200 kN |

| Shots/minute max. | 4 |

| Max. product height in mm | 100-150 |

With two drying stations, the MT/FP-80-2 is somewhat larger and produces up to 100 kilograms per hour (Consistency, 35%).

| MACHINE TYPE | MT/FP-80-2 |

| Output kg/h up to | 60-80-100 (Consistency, 35%) |

| 1180 x 900 | |

| Semi-rotating | |

| No. of drying stations | 2 |

| Pressing force | Servo hydraulic 200 kN |

| Shots/minute max. | 4 |

| Max. product height in mm | 100-150 |

The most compact of our pulp thermoforming machines, the MT/FP80-1 has one drying station and produces approximately 40-60 kilograms per hour (consistency, 35%).

| MACHINE TYPE | MT/FP-80-1 |

| Output kg/h up to | 40-60 (Consistency, 35%) |

| Table size mm x mm | 1180 x 900 |

| Semi-rotating | |

| No. of drying stations | 1 |

| Pressing force | Servo hydraulic 200 kN |

| Shots/minute max. | 4 |

| Max. product height in mm | 100-150 |

The most compact of our pulp thermoforming machines, the MT/FP54-1 has one drying station and produces approximately 40 kilograms per hour.

| MACHINE TYPE | MT/FP-54-1 |

| Output kg/h up to | 40 |

| Table size mm x mm | 1100 x 900 |

| Semi-rotating | |

| No. of drying stations | 1 |

| Pressing force | Servo hydraulic 100 kN |

| Shots/minute max. | 2 |

| Max. product height in mm | 150 |

With two drying stations, the MT/FP-54-2 is somewhat larger and produces up to 60 kilograms per hour.

| MACHINE TYPE | MT/FP-54-2 |

| Output kg/h up to | 1100 x900 |

| Semi-rotating | |

| No. of drying stations | 2 |

| Pressing force | |

| Shots/minute max. | 3 |

| Max. product height in mm | 150 |

This pulp thermoforming machine is our top model. It allows the production of high volumes by automated stock preparation and increased drying capacity.

| MACHINE TYPE | MT/FP-54-3 |

| Output kg/h up to | 80 |

| Table size mm x mm | 1100 x900 |

| Semi-rotating | |

| No. of drying stations | 3 |

| Pressing force | |

| Shots/minute max. | 4 |

| Max. product height in mm | 150 |