Features

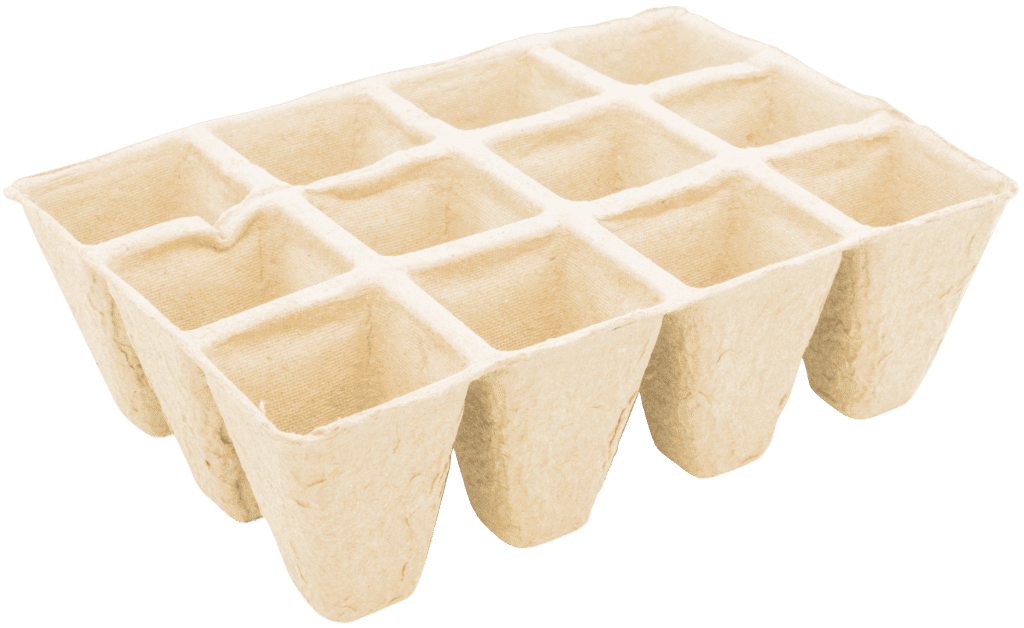

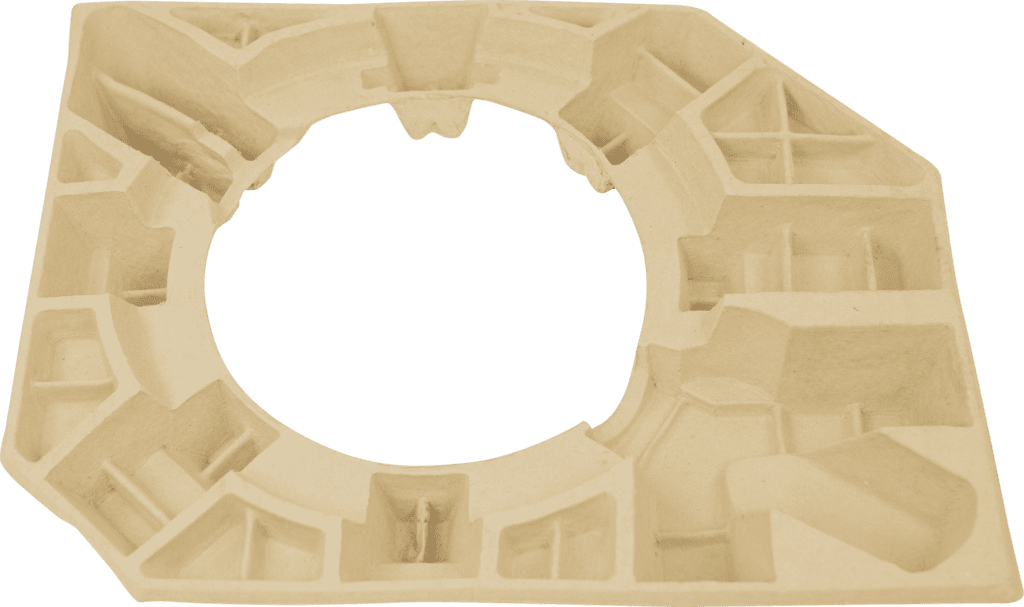

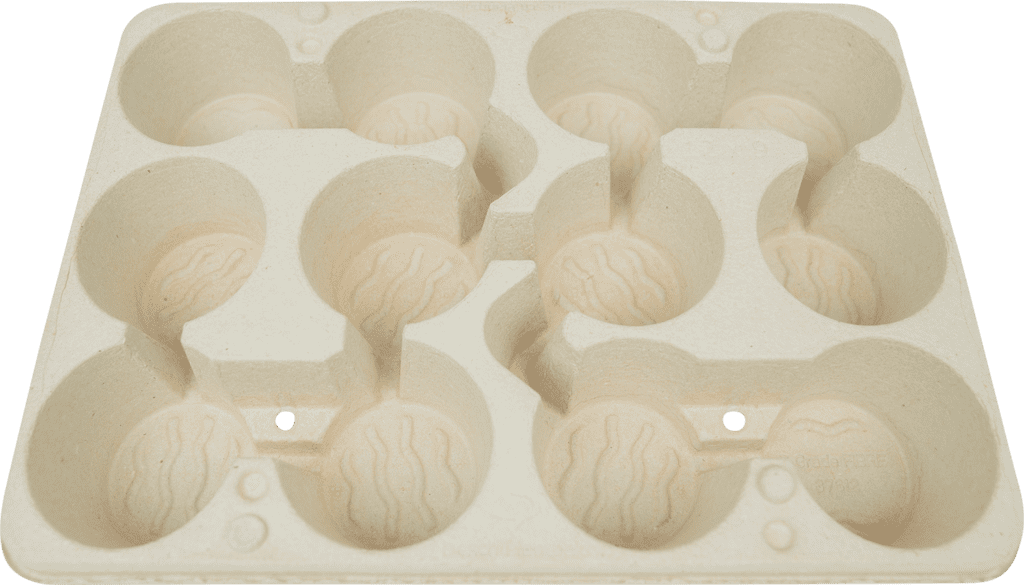

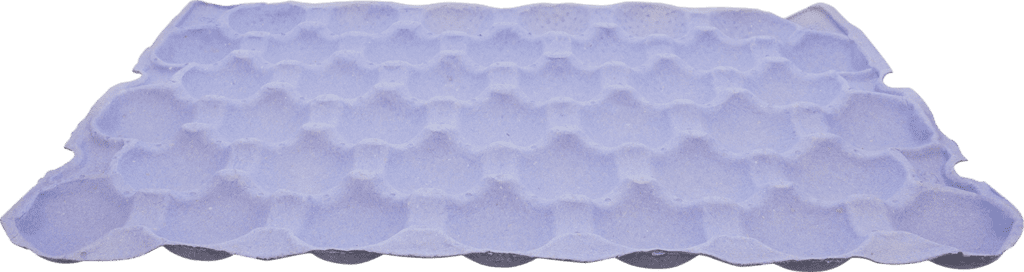

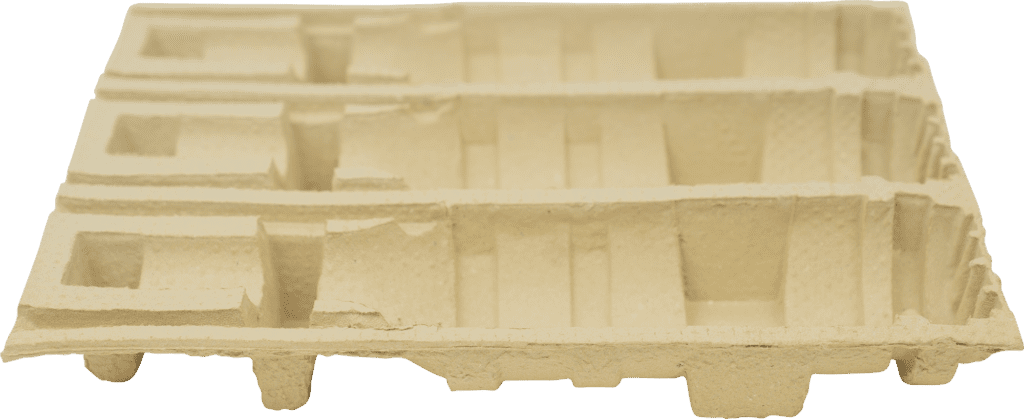

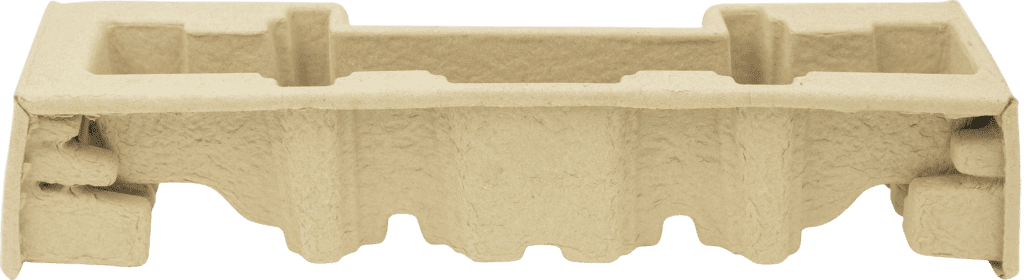

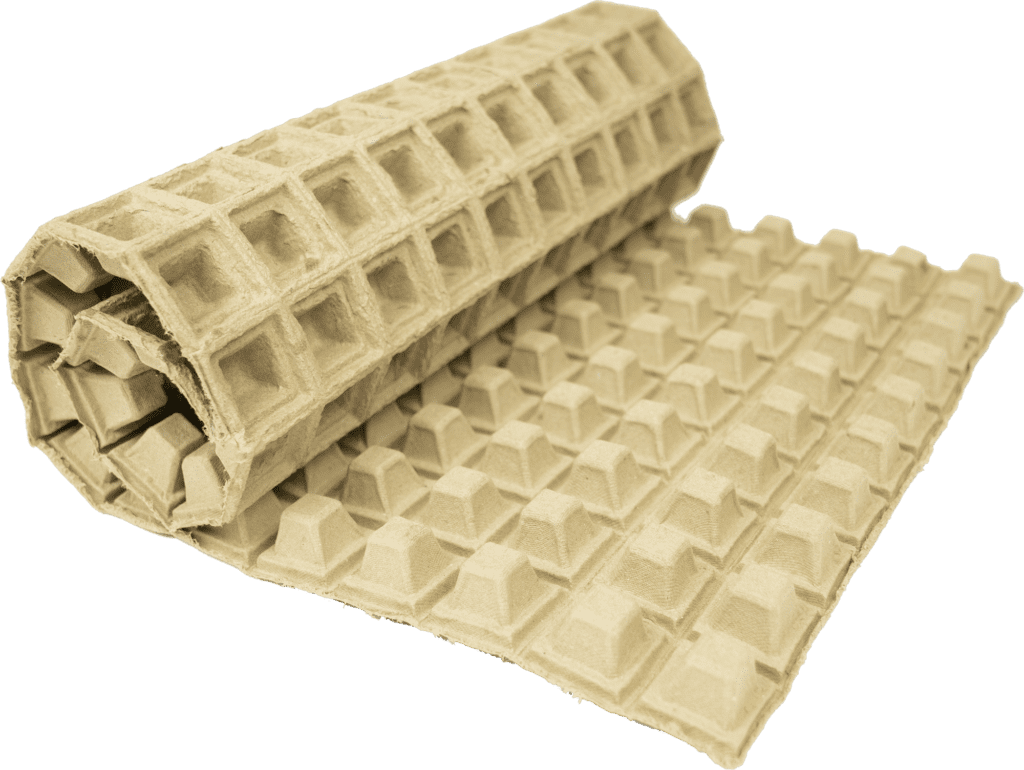

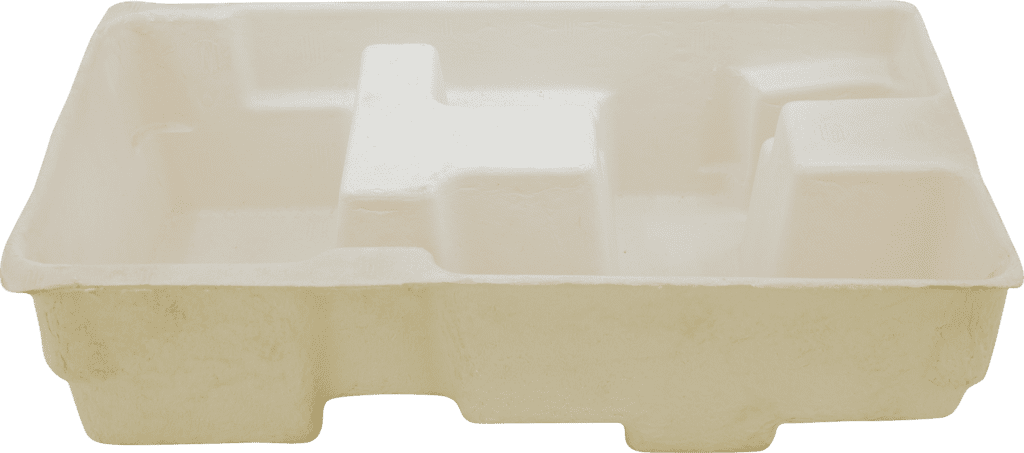

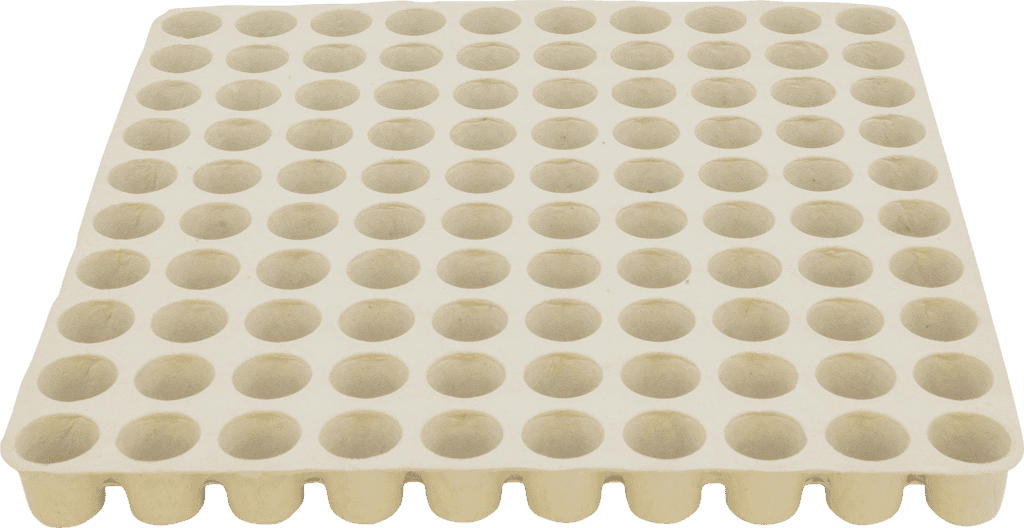

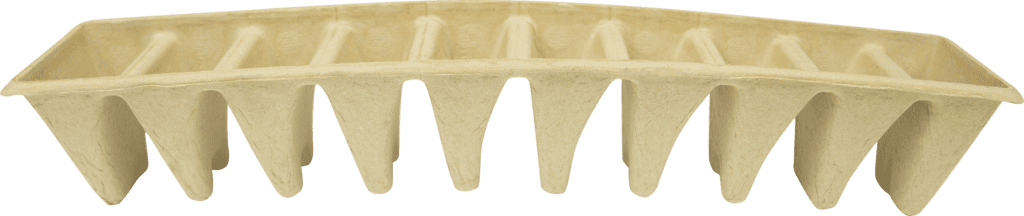

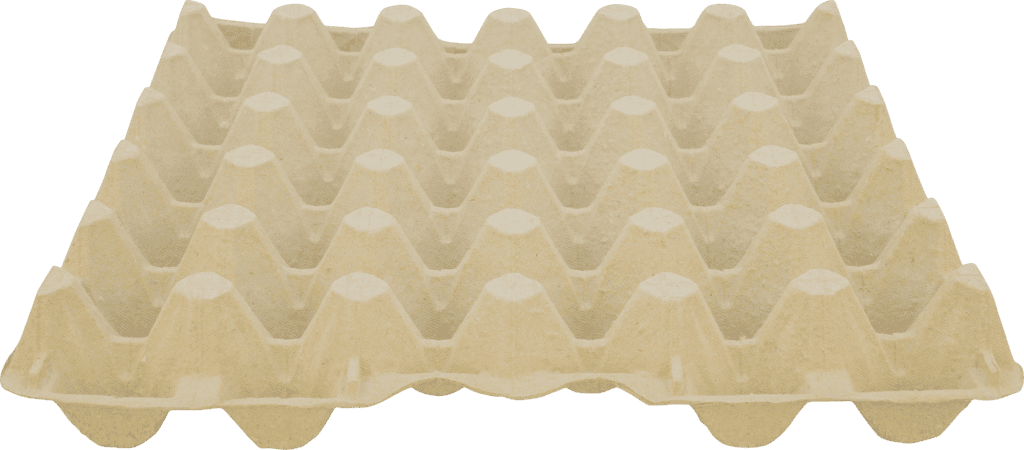

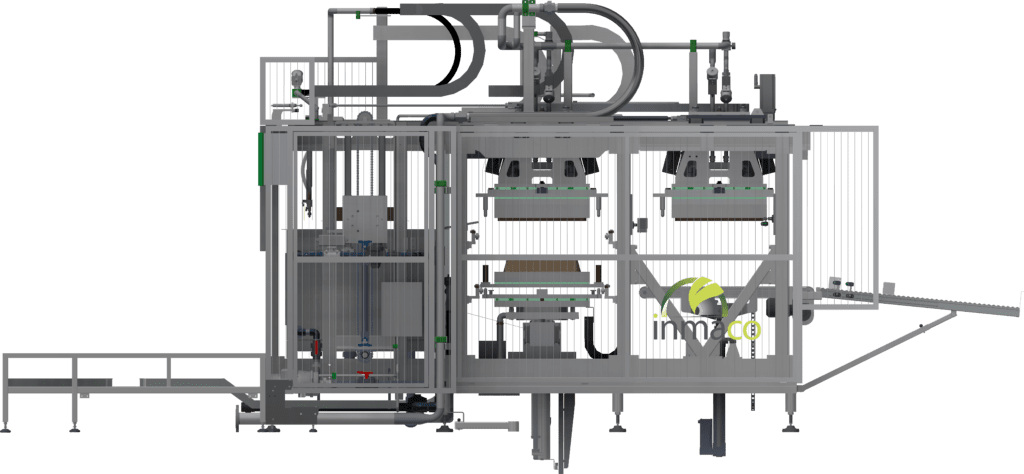

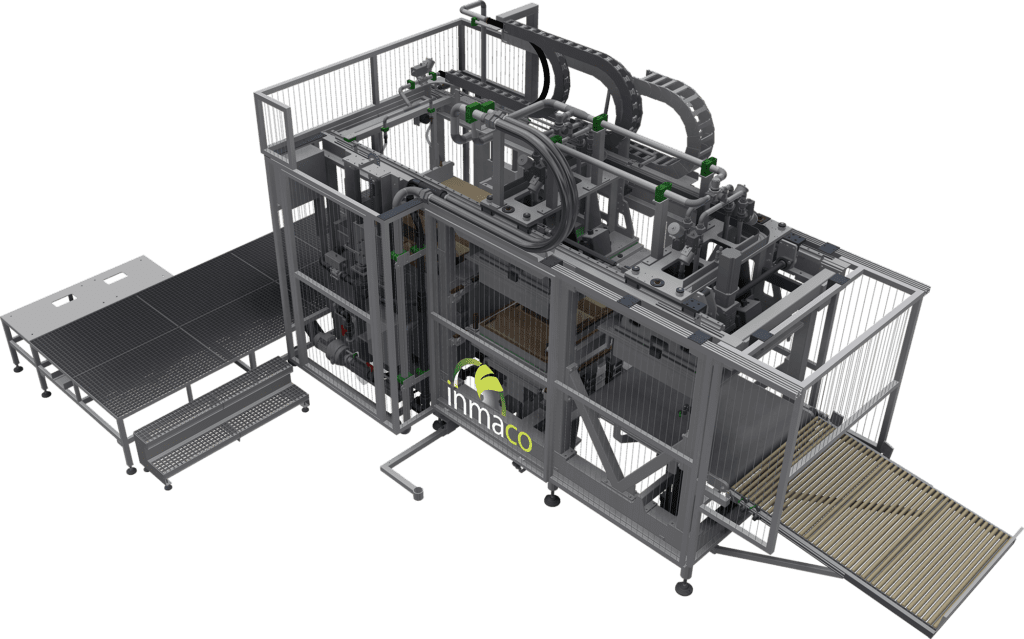

- Accurate dimensions and a perfect shape for enhanced appearance

- Smooth and dust-free surface on both sides

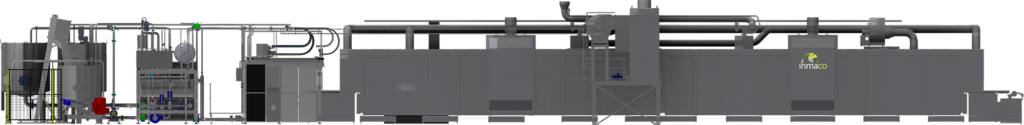

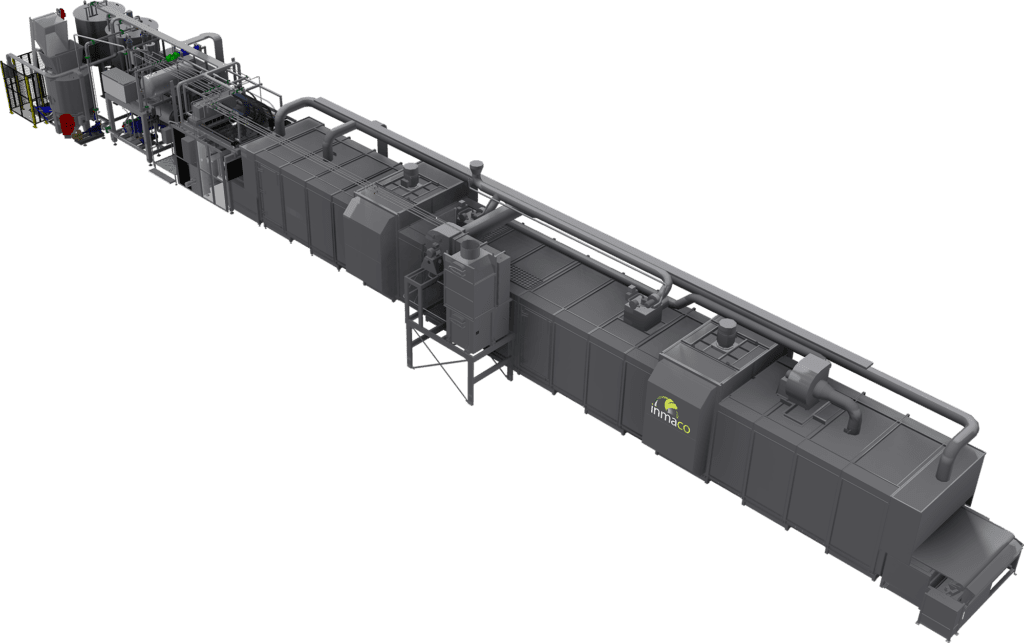

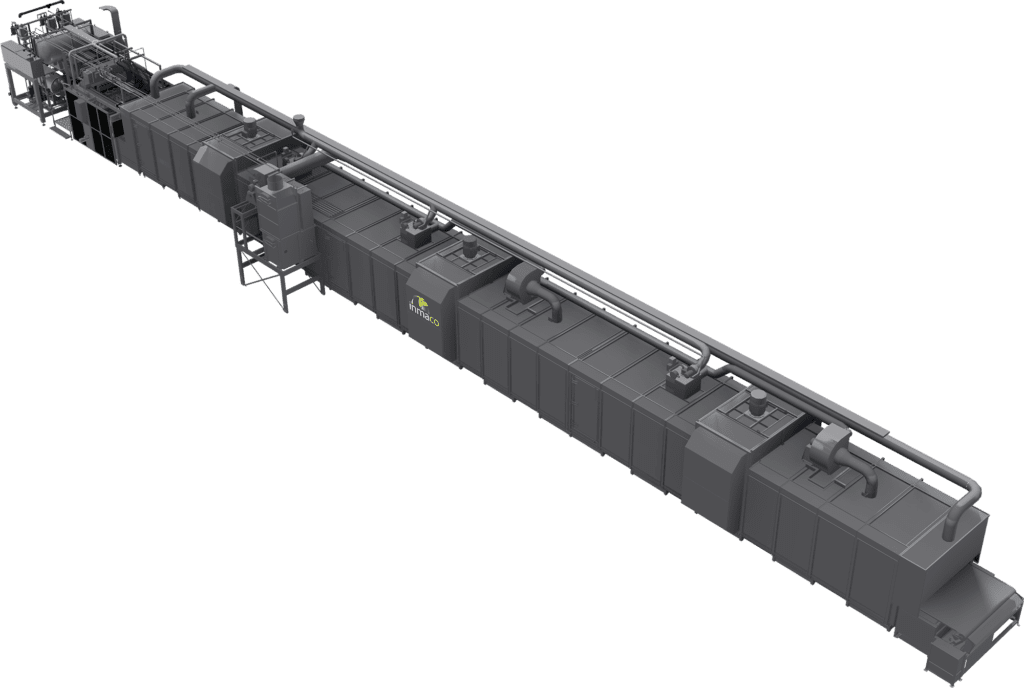

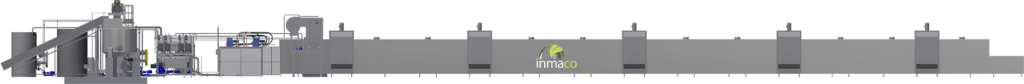

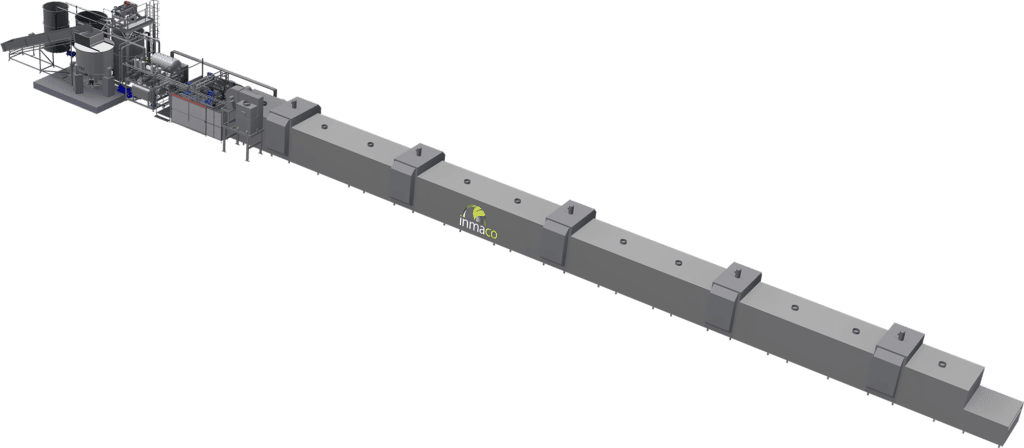

- Three drying stations with an output of 100 kilograms per hour (Consistency, 35%)

- Servo-driven

- Reciprocating-rotating forming station: fast tool change

- Energy-saving design, due to omittance of a bulk dryer

- Can be printed or embossed and trimmed

- Complete system, including stock preparation